HORIZONTAL HIGH PRESSURE / HIGH SPEED STERILIZER : CYLINDRICAL

End ring hydraulically formed without joints to sustain required pressure.All other joints Argon Arc Welded Two safety valves and a pressure switch Design stage is desirable. to prevent accidental pressure build up. Low water level protection for heaters. Pressure lock device for the door. Hydro-statically tested

Key Features

- Premium Quality Equipment

- Free Installation Support

- Manufacturer Warranty

- 24/7 Technical Support

Product Description

Product: Horizontal High Pressure / High Speed Sterilizer – Cylindrical

Overview

The Horizontal High Pressure / High Speed Sterilizer (Cylindrical) is a heavy-duty steam sterilization autoclave designed for use in hospitals, CSSDs, nursing homes, laboratories, and other healthcare or industrial settings where reliable sterilization of medical instruments, dressings, glassware, and other heat-resistant items is required. This front-loading horizontal unit uses high-pressure saturated steam to achieve complete microbial inactivation, ensuring instrument safety and compliance with sterilization standards.

Construction & Safety

Cylindrical Chamber: End ring hydraulically formed without joints to sustain required pressure; all other joints are argon arc welded for strength and leak resistance.

Safety Features: Dual safety valves and a pressure switch to prevent accidental pressurization; pressure-lock device on the door ensures the sterilizer cannot be opened under pressure; low water level protection for heaters.

Hydrostatic Tested: The chamber and vessel undergo rigorous hydrostatic testing to ensure structural integrity and safety before delivery/installation.

Operating Principle

This sterilizer uses high-pressure saturated steam to sterilize equipment. The steam introduces heat and moisture uniformly throughout the chamber, efficiently destroying bacteria, spores, and other pathogens. Standard operation modes include:

Low Speed: 9 kW heating, 121 °C at 1.2 kg/cm²

High Speed: 18 kW heating, 134 °C at 2.1 kg/cm²

These modes allow flexibility based on load type and throughput requirements.

Typical Uses

Sterilizing surgical instruments, orthopaedic sets, and cardiac trays

Processing dressings, glassware, rubber/plastic goods, and other reusable hospital items

Bulk sterilization in CSSD or laboratory workflows

(Note: Smaller sizes may not accommodate large packs or sets; see application suitability chart).

Stand & Mounting

Unit is provided on sturdy SS or MS powder-coated stand/frame for floor mounting and secure installation.

General Benefits

Uniform Steam Penetration: The cylindrical design maximizes steam circulation and heat distribution, improving sterilization consistency.

Robust & Durable: Stainless steel construction resists corrosion and supports long life under high-pressure cycling.

Safety & Compliance: Equipped with standard safety interlocks, valves, and monitoring features to meet healthcare sterilization requirements. |

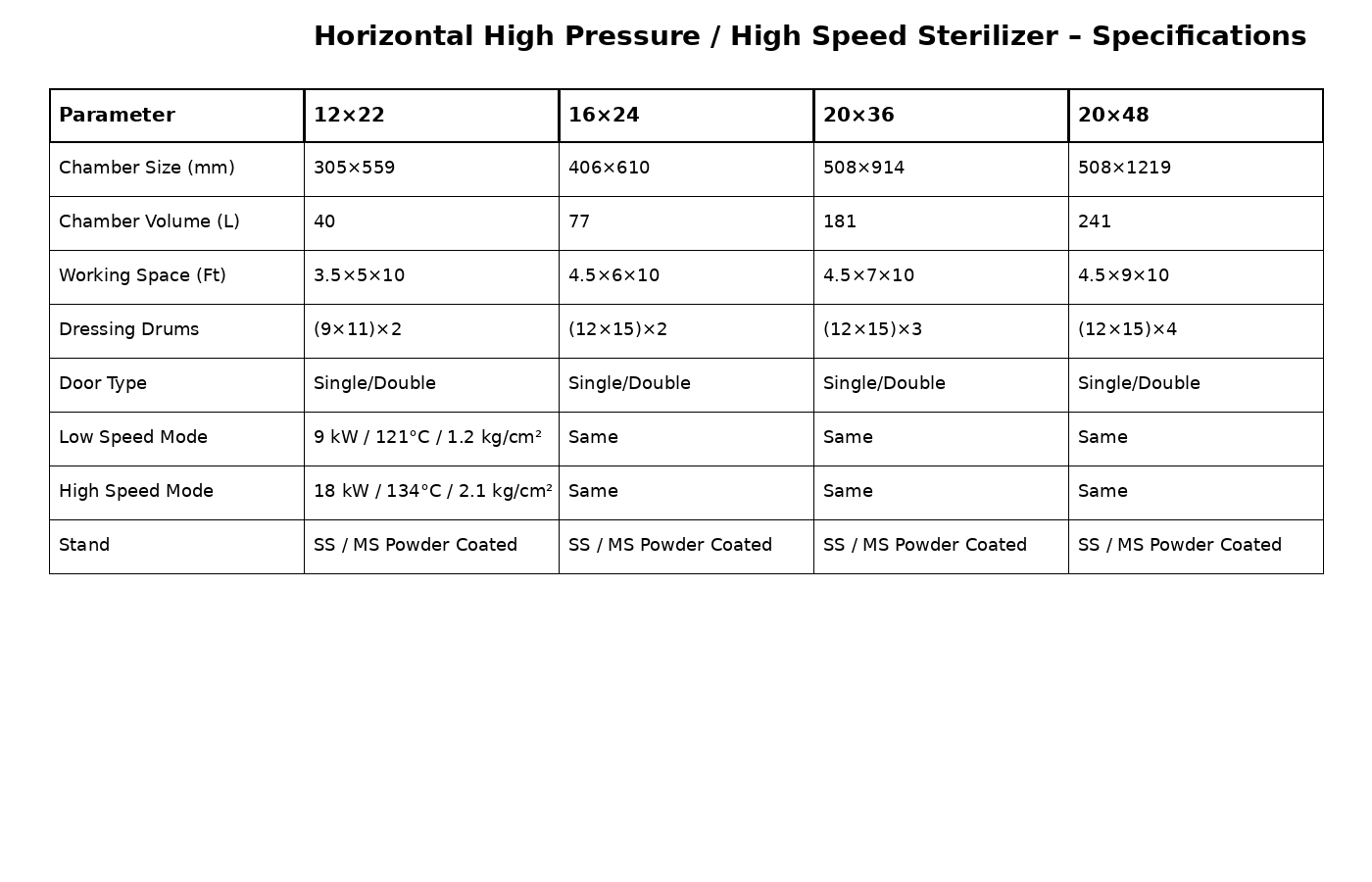

Technical Specifications

No specifications available for this product.

Download Documents

No documents available for download.